Role: Product Designer Fellow

Company: IDEO

Client: Ford Motor Co.

The IDEO CoLab brings together like-minded organizations to understand and shape how emerging technologies will affect our world. We focus on AR/VR, AI, IOT, and Blockchain for human centered applications in the areas of money, energy, food, transportation, and platform tech.

Blokmotiv is currently under continued internal development at IDEO CoLab and Ford Motor Co. I had the pleasure of working on this project together with Rob Sieg and Gloria Chua.

2017

Blockmotiv

In the summer of 2017, I had the opportunity to join IDEO CoLab for a 3 month fellowship in San Francisco, CA. CoLab is the Research and Design arm of IDEO that focuses on surfacing new questions, prototyping with emerging technologies, and bringing them closer to market. Working with industry partners like Ford Motor Company, NASDAQ, and Blue Cross Blue Shield, the CoLab works to imagine how these emerging technologies will impact key human systems.

I spent a majority of my time at IDEO working on a collaborative project with Ford Motor Company. Interested in the unique and complex system of blockchain technology, my team and I explored possibilities surrounding the concept of issuing digital identities to physical items. For a quick explanation of what blockchain tech is and how it works, please read this.

During our preliminary research, we uncovered a compelling use case that helped us realize our final prototype. There is currently a $45 billion market for counterfeit automotive parts, making them the 5th most commonly counterfeited category on the market. Airbags, one of the most important safety features in a vehicle, are a large part of this black market. As we delved deeper to better understand the problem, we settled on a guiding question for our overall project:

As we began to study the airbag supply chain we started to understand much more about our problem and the origins of counterfeit airbags. Airbag components are often manufactured by disparate companies, then sent to another for assembly into the final product. From there they are shipped to an OEM like Ford where they are installed into vehicles. In the case of an airbag replacement after a collision, mechanics and automotive shops can order airbags directly from the assembly company as well. One insight we uncovered through our research is that production runs of components have a batch number, but no way to track individual parts. In addition, airbag assemblers apply a tracking barcode to a completed airbag so they can track it until it ships out. OEMs register batch numbers of airbags from assemblers, but don't currently have a way to tell which car contains a specific airbag. None of these tracking systems interface with one another and little information is shared between these production stakeholders. Vehicle owners and mechanics are on the outside of this loop, having even less info about the parts installed in their vehicle. Something about recalls

Unfortunately the high price of a certified airbag can be a deterrent to installers and drivers, so they sometimes turn to non-certified resellers. Many of these lower cost airbags are the counterfeits we identified previously. Called "Frankestein airbags", these counterfeits are often real components but not for the vehicle they are being installed into. For example, a Frankenstein airbag may be comprised of a Ford outside cover, a Honda bag, and a Toyota inflator. In some cases they still functional parts that will deploy in the event of a collision, but they actually become more dangerous than not having an airbag installed at all. Airbags systems are designed for the specific geometry of a particular vehicle's cabin and, if not matched with the vehicle they belong to, can actually increase a vehicle occupant's chance to injury or death.

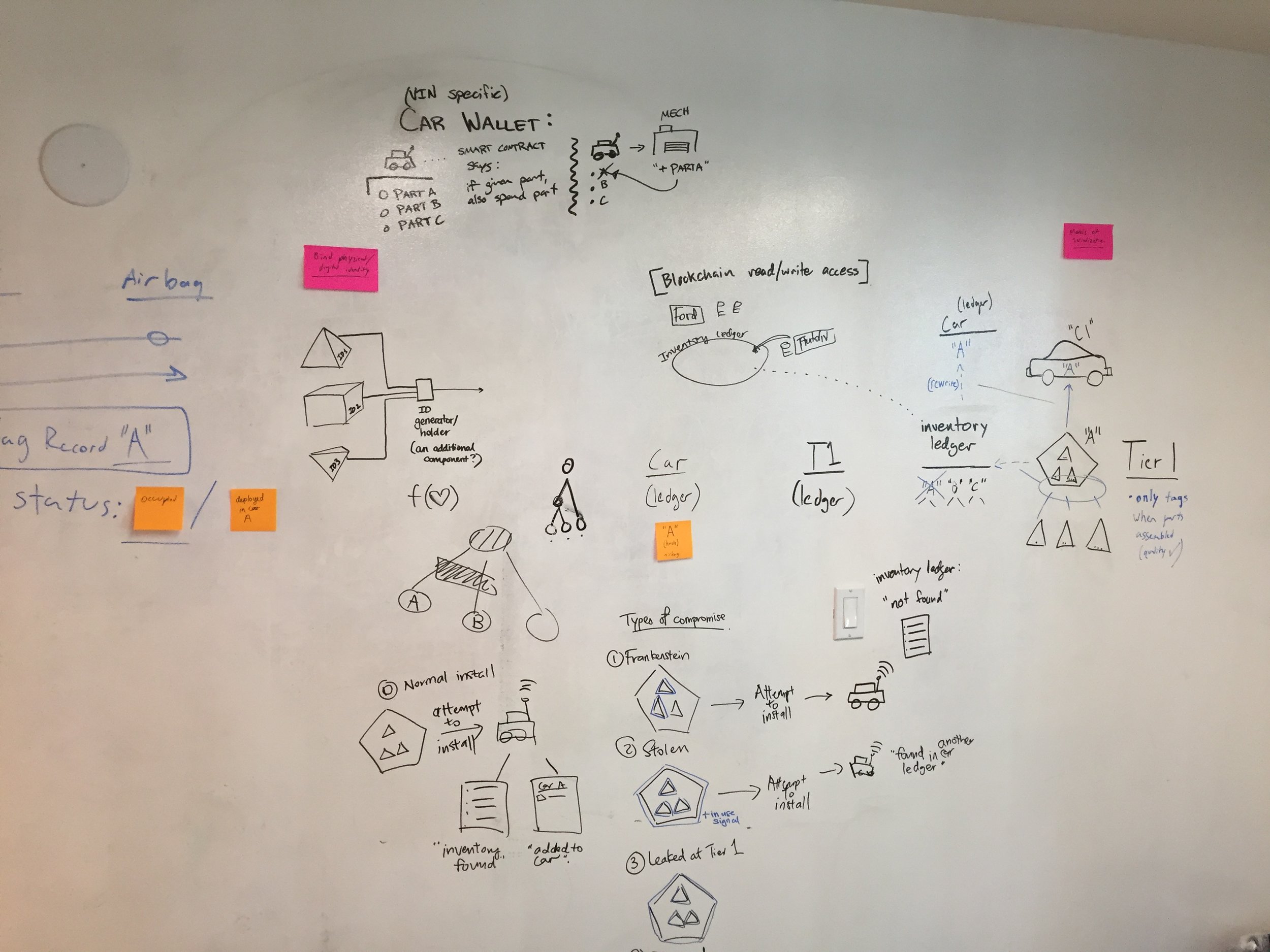

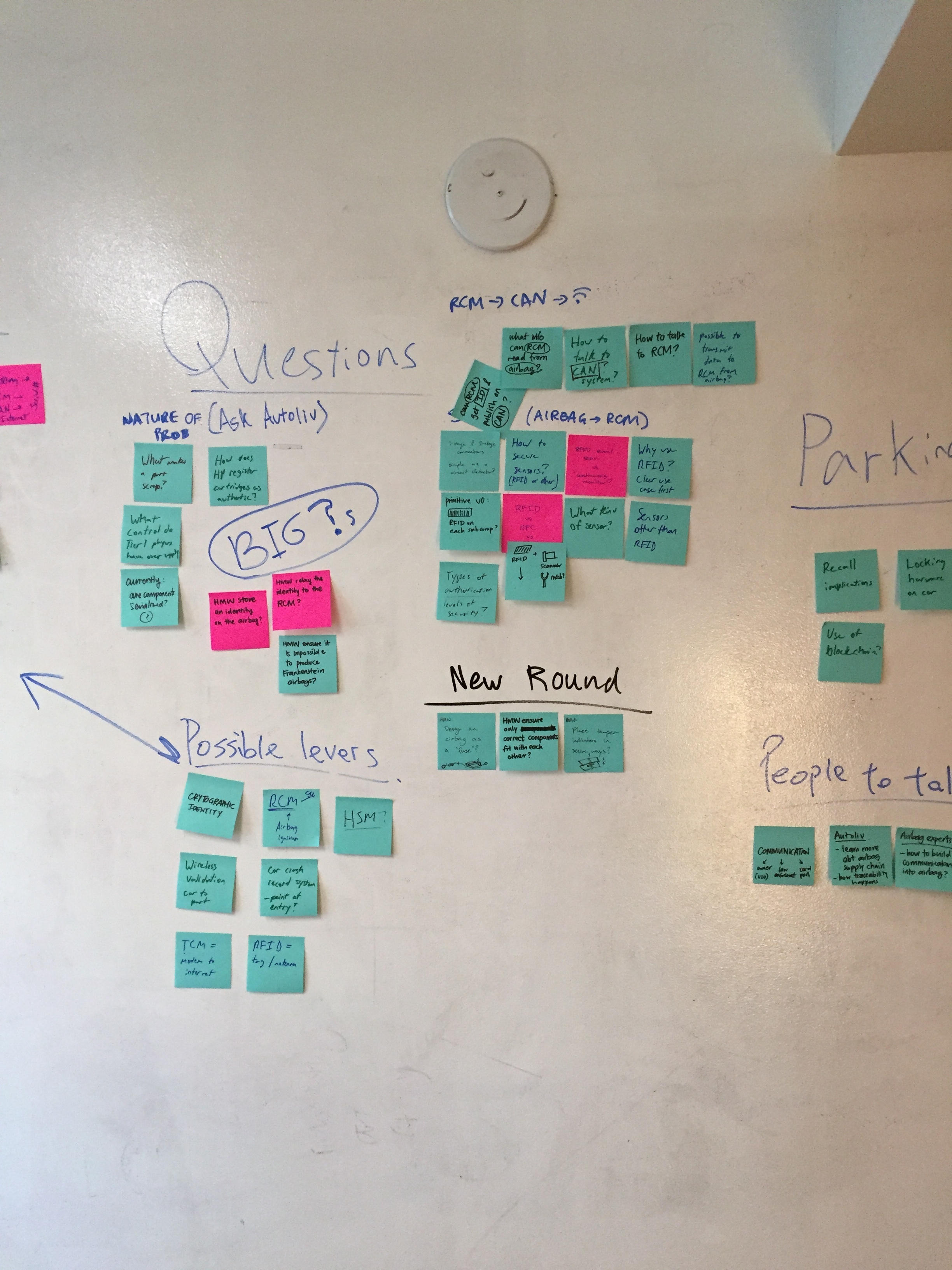

My team began to hone in on a possible solution for the challenges we had uncovered. If we could find a way to leverage the immutable ledger of blockchain to serve as a record of the creation, movement, and installation of airbags, we might be able to build a single system for all these stakeholders to be able to access. To do so, we would need to find a way to assign identity to the airbags and read that identity as it moves through the system. Additionally, we felt that it was important to service the entire system, assigning identities not only to the airbags, but to their individual components as well. With this systems approach, we also knew that our final product would need to serve as an accessible platform for all out major stakeholders as well. This system would depend on the involvement of parts manufacturers, vehicle OEMs, owners, mechanics, and more.

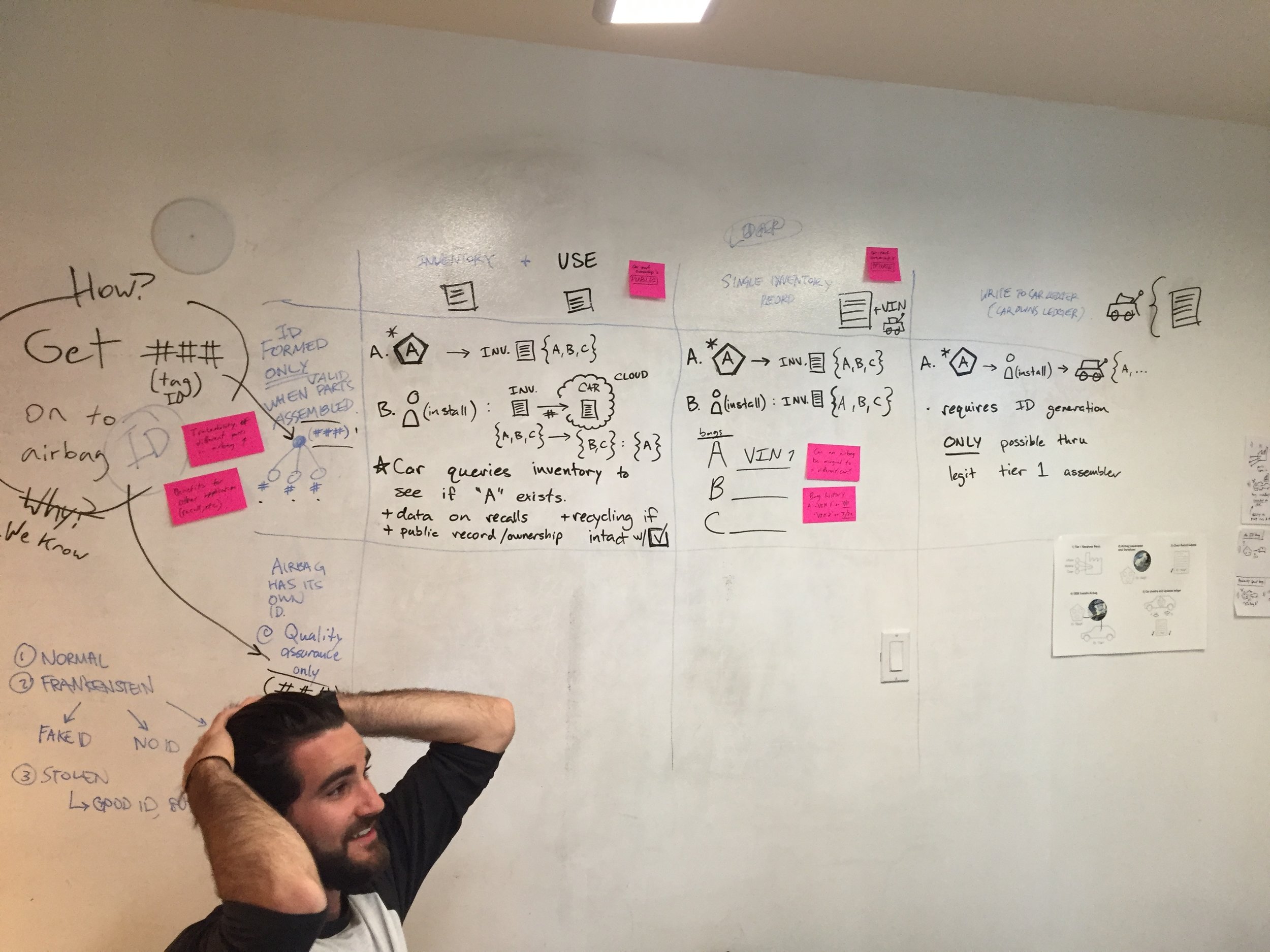

The result of our work was Blokmotiv, a system that uses aggregated identity as a new framework for the life cycle of airbags. Component parts each receive unique IDs, then all the parts of an assembly are also given an additional ID after they are joined. All of this activity is recorded on Blokmotiv's blockchain, acting as a record of all events. This allows us to know one airbag from another, and lets us know what parts it was made from.

In order to demonstrate the functionality of Blokmotiv, we knew that a physical prototype of the manufacture/assembly process would be the best way to do so. Users take turns acting as different stakeholders in the process. First, they are asked to choose three parts and assemble a new airbag from them, scanning each part separately. Once that's complete, the separate ID's are then hashed together when scanned as an assembled airbag unit. Data recording and storage is shown on the screen as this takes place and highlights how the system is used (see below). Next, the user is asked to play the part of a repair mechanic replacing an airbag. Once installed, the system checks the blockchain to verify that is is a valid part with underlying components. If it's a good airbag it is accepted and logs a good installation, and if it's bad, it rejects it and sends an alert to certain stakeholders and authorities.

This project demonstrates a great use case for blockchain technology in supply chain management, particularly with critical safety parts. During our development phase, we also stumbled upon other application areas where this system could easily be adapted to create positive impact, such as hospital equipment or even food production. This platform was designed in part for autonomous vehicles, but we found that the possibilities are endless.